-

CP101Polyester-based TPU

Features

Excellent Processing Properties, Fast Setting Time, No Migration, Cost Saving

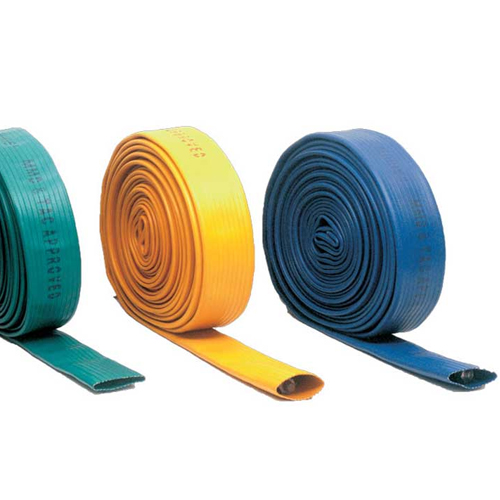

Applications

Phone & Pad Cover, Footwear, Compounding & Modifier, Wheel & Castor, Hose & Tube, Overmolding etc.

-

TYPICAL COMPONENT PROPERTIES

Properties Standard Unit Value Density ASTM D792 g/cm3 1.19 Hardness ASTM D2240 Shore A 83 Tensile Strength ASTM D412 MPa 35 100% Modulus ASTM D412 MPa 5 300% Modulus ASTM D412 MPa 9 Elongation at Break ASTM D412 % 550 Tear Strength ASTM D624 KN/m 85 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 6-8hours at 70-80℃ is advisable, in a desiccant-air dryer. The suggested processing-temperature profiles for injection & extrusion are depicted in the figure below.

Processing Guide for Injection Molding

Item Parameter Nozzle(°C) 200 Metering Zone(°C) 195 Compression Zone(°C) 190 Feeding Zone(°C) 185 Injection Pressure(bar) 70 Processing Guide for Extrusion

Item Parameter Die(°C) 185 Adapter(°C) 190 Metering Zone (°C) 185 Compression Zone (°C) 180 Feeding Zone (°C) 175 -

HSE INFORMATION

Please take MSDS for reference

-

CP104Polyester-based TPU

◼ Features

Excellent Processing Properties, Fast Setting Time, No Migration, Cost Saving

◼ Applications

Wheel & Castor, Injecting, etc.

-

TYPICAL COMPONENT PROPERTIES

Properties Standard Unit Value Density ASTM D792 g/cm3 1.21 Hardness ASTM D2240 Shore D 55 Tensile Strength ASTM D412 MPa 35 100% Modulus ASTM D412 MPa 10 300% Modulus ASTM D412 MPa 20 Elongation at Break ASTM D412 % 400 Tear Strength ASTM D624 KN/m 140 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 6-8hours at 70-80℃ is advisable, in a desiccant-air dryer. The suggested processing-temperature profiles for injection & extrusion are depicted in the figure below.

Processing Guide for Injection Molding

Item Parameter Nozzle(°C) 215 Metering Zone(°C) 210 Compression Zone(°C) 205 Feeding Zone(°C) 200 Injection Pressure(bar) 90 Processing Guide for Extrusion

Item Parameter Die(°C) 195 Adapter(°C) 190 Metering Zone (°C) 185 Compression Zone (°C) 180 Feeding Zone (°C) 175 -

HSE INFORMATION

Please take MSDS for reference

-

CP105Polyester-based TPU

◼ Features

Good Flowability, No Migration, Good Low Temperature Flexibility, Favorable Hand Fee.

◼ Applications

Footwear, Compounding, Watch Belt etc.

-

TYPICAL COMPONENT PROPERTIES

Properties Standard Unit Value Density ASTM D792 g/cm3 1.19 Hardness ASTM D2240 Shore A 75 Tensile Strength ASTM D412 MPa 20 100% Modulus ASTM D412 MPa 3 300% Modulus ASTM D412 MPa 6 Elongation at Break ASTM D412 % 650 Tear Strength ASTM D624 KN/m 65 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 3-4 hours at 80-95℃ is advisable.

Processing Guide for Injection Molding

Item Parameter Nozzle(°C) 195 Metering Zone(°C) 190 Compression Zone(°C) 185 Feeding Zone(°C) 180 Injection Pressure(bar) 80 Processing Guide for Extrusion

Item Parameter Die(°C) 185 Adapter(°C) 190 Metering Zone (°C) 185 Compression Zone (°C) 180 Feeding Zone (°C) 175 -

HSE INFORMATION

Please take MSDS for reference

-

CP106Polyester-based TPU

◼ Features

Low Temperature Flexibility, Oil Resistance, Excellent Elasticity, Abrasion Resistance, etc.

◼ Applications

Film & Sheet, Hose & Tube, Belting, Wire & Cable, Elastics, Shoulder Girdle, Compounding, etc.

-

TYPICAL COMPONENT PROPERTIES

Properties Standard Unit Value Density ASTM D792 g/cm3 1.19 Hardness ASTM D2240 Shore A 81 Tensile Strength ASTM D412 MPa 32 100% Modulus ASTM D412 MPa 5 300% Modulus ASTM D412 MPa 9 Elongation at Break ASTM D412 % 550 Tear Strength ASTM D624 KN/m 90 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 3-4 hours at 80-90℃ is advisable..

Processing Guide for Injection Molding

Item Parameter Nozzle(°C) 205 Metering Zone(°C) 210 Compression Zone(°C) 205 Feeding Zone(°C) 180 Injection Pressure(bar) 80 Processing Guide for Extrusion

Item Parameter Die(°C) 190 Adapter(°C) 195 Metering Zone (°C) 195 Compression Zone (°C) 185 Feeding Zone (°C) 170 -

HSE INFORMATION

Please take MSDS for reference

-

CP107Polyester-based TPU

◼ Features

Fast Crystallization Rate, Good Transparence, Abrasion Resistance, etc.

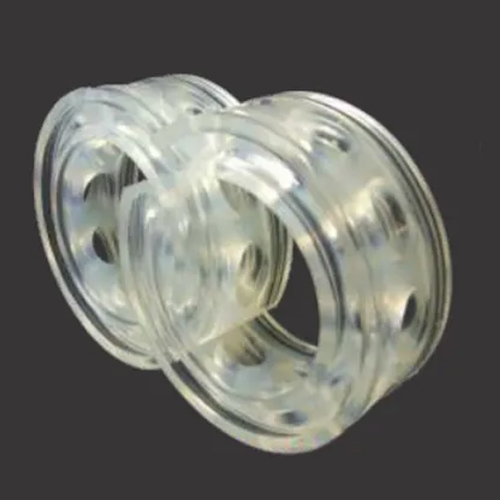

◼ Applications

Hose & Tube, Caster, Seals, Shoe Material, etc.

-

TYPICAL COMPONENT PROPERTIES

Properties Standard Unit Value Density ASTM D792 g/cm3 1.21 Hardness ASTM D2240 Shore D 57 Tensile Strength ASTM D412 MPa 45 100% Modulus ASTM D412 MPa 15 300% Modulus ASTM D412 MPa 30 Elongation at Break ASTM D412 % 400 Tear Strength ASTM D624 KN/m 180 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 3-4 hours at 100-110℃ is advisable.

Processing Guide for Injection Molding

Item Parameter Nozzle(°C) 215 Metering Zone(°C) 215 Compression Zone(°C) 215 Feeding Zone(°C) 195 Injection Pressure(bar) 80 Processing Guide for Extrusion

Item Parameter Die(°C) 200 Adapter(°C) 205 Metering Zone (°C) 205 Compression Zone (°C) 200 Feeding Zone (°C) 180 -

HSE INFORMATION

Please take MSDS for reference

-

CP107Polyester-based TPU

◼ Features

Good Abrasion Resistance, Excellent Mechanical Property, Oil / Solvent Resistance.

◼ Applications

Casters, Heel lift, injection molding, etc.

-

TYPICAL COMPONENT PROPERTIES

Properties Standard Unit Value Density ASTM D792 g/cm3 1.21 Hardness ASTM D2240 Shore A 65 Tensile Strength ASTM D412 MPa 55 100% Modulus ASTM D412 MPa 22 300% Modulus ASTM D412 MPa 40 Elongation at Break ASTM D412 % 350 Tear Strength ASTM D624 KN/m 200 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 3-4 hours at 60-70℃ is advisable.

Processing Guide for Injection Molding

Item Parameter Nozzle(°C) 225 Metering Zone(℃) 220 Metering Zone (°C) 220 Compression Zone (°C) 215 Injection Pressure(bar) 95 -

HSE INFORMATION

Please take MSDS for reference

-

CP109Polyester-based TPU

◼ Features

High Bonding Strength and Peel Strength, Excellent Extrusion Consistency, Excellent solubility performance.

◼ Applications

Hot Melt Films and Tapes, Solvent-based Adhesives, Footwear Adhesives, Fire Hose Adhesives, etc.

-

TYPICAL COMPONENT PROPERTIESMinimum Activation Temperature

Properties Standard Unit Value Density ASTM D792 g/cm3 1.2 Hardness ASTM D2240 Shore A 95 Viscosity (15% in MEK 25Cº) ISO 3219 mpa.s 2500-3500 Max.Toluene in solvents - % 30-35 Tensile Strength ASTM D412 MPa 40 Tear Strength ASTM D624 KN/m 100 Bonding strength PVCvsPVC,After 10min kg/2.5cm 8-13 Crystallization Rate - - Fast Tack-free time - min 15 - ℃ 55-65 -

PROCESSING GUIDEFor optimum results, previous drying of the product during 6-8hours at 70-80°C is advisable, in a desiccant-air dryer. The suggested processing-temperature profiles for injection & extrusion are depicted in the figure belo.

Solution processing advice(Y: soluble S: swelling)

Item Parameter DMF Y MEK Y Acetone Y Trichloromethane S Ethyl acetate S Toluene S Processing Guide for Extrusion

Item Parameter Die(°C) 185 Adapter(°C) 190 Metering Zone (°C) 180 Compression Zone (°C) 170 Feeding Zone (°C) 120 -

HSE INFORMATION

Please take MSDS for reference

-

CP110Polyester-based TPU

◼ Features

High Bonding Strength and Peel Strength, Excellent Extrusion Consistency, Excellent solubility performance.

◼ Applications

Hot Melt Films and Tapes, Solvent-based Adhesives, Footwear Adhesives, Fire Hose Adhesives, etc.

-

TYPICAL COMPONENT PROPERTIESMinimum Activation Temperature

Properties Standard Unit Value Density ASTM D792 g/cm3 1.2 Hardness ASTM D2240 Shore A 95 Viscosity (15% in MEK 25Cº) ISO 3219 mpa.s 1500-2500 Max.Toluene in solvents - % 30-35 Tensile Strength ASTM D412 MPa 40 Tear Strength ASTM D624 KN/m 100 Bonding strength PVCvsPVC,After 10min kg/2.5cm 8-13 Crystallization Rate - - Fast Tack-free time - min 15 - ℃ 55-65 -

PROCESSING GUIDE

Solution processing advice(Y: soluble S: swelling)

Item Parameter DMF Y MEK Y Acetone Y Trichloromethane S Ethyl acetate S Toluene S Processing Guide for Extrusion

Item Parameter Die(°C) 185 Adapter(°C) 190 Metering Zone (°C) 180 Compression Zone (°C) 170 Feeding Zone (°C) 100 -

HSE INFORMATION

Please take MSDS for reference